BMOW’s product Floppy Emu needs a male DB-19 connector to mate with vintage Apple computers, but these connectors haven’t been manufactured in decades. For two years I’ve been scraping by with “new old stock” DB-19’s from warehouses around the world, but that supply has almost completely dried up. I recently found a few hundred more, but it’s clear that the end will come sometime in 2016. To prepare for the worst, I’ve been working on a design for a DB-19 substitute. After more experiments, today I decided that this path has reached a dead end.

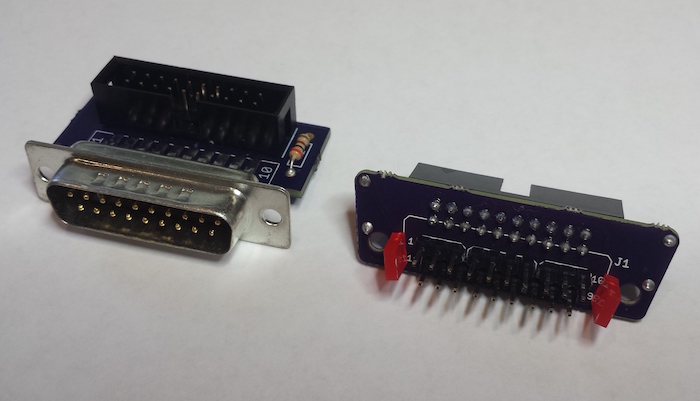

The current DB-19 adapter for Floppy Emu is shown at left, in the photo above. It consists of a small PCB with an edge-mounted male DB-19 at one end, and a 10×2 shrouded header connector at the other end. A ribbon cable plugs in to the 10×2 header, and the DB-19 plugs into the computer’s external disk port, and everything is great.

Designing a Substitute

The basic idea of a DB-19 substitute is to replace the male DB-19 with sections of 0.1 inch male header arranged in a DB-19 pattern, while keeping everything else more or less the same. I first explored this idea a year ago, and the prototype worked reasonably well, but had its share of problems. The 0.1 inch pin spacing didn’t quite match the 0.109 inch spacing of a D-SUB connector, and it put square pins into round holes. Without a surrounding shield, it was too easy to misalign the substitute connector while plugging it in, so I added two rectangular LEDs as structural elements to serve as mechanical guides. It sounds dodgy, but it passed some quick tests on several different Apple computers. Then I put the prototype away in a drawer, and didn’t think about it again.

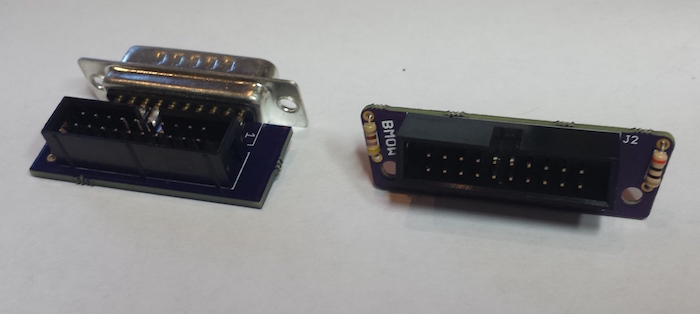

This week I received a new PCB for what I hoped would be the final DB-19 substitute design. I shrunk the overall size of the PCB, and gave it a trapezoid shape with rounded edges to invoke the spirit of a real D-SUB. I split up the 0.1 inch headers into a larger number of smaller sections, so the average offset from the nominal 0.109 inch spacing was reduced. And taking a popular suggestion from the first prototype, I made the LEDs into more than mere mechanical guides – now they light up! It’s a pretty cool effect. A side-by-side comparison of this new DB-19 substitute with the current model DB-19 adapter is shown above, and a rear view of the same connectors is below:

Quality Control Failure

The new DB-19 substitute passed all my initial tests, and everything was looking good. But once I started testing more carefully, I realized that the connection wasn’t solidly reliable. It worked 100% of the time on my Mac Plus, Apple IIgs, and a borrowed Apple IIc+. But when plugged into the daisy chain connector of an Apple 3.5 Drive, it only worked about half the time. And when plugged into an Apple IIc, it never worked, unless I pushed on the connector with my finger during disk I/O. Ugh. At first I thought maybe this new DB-19 substitute had some new problem, but when I tested last year’s version more carefully, it had the same issues.

I think there are several things preventing this from working reliably. While putting square pins into round holes sounds crazy, I think that’s the least of the problems. What’s more significant is that the diagonal length of each pin’s cross section is probably slightly different than the diameter of the round pin that’s supposed to be there. Combined with the slight misalignment of some pins, I believe this leads to weak or no contact for those pins inside the female connector. I don’t know if the female’s interior has flat wipers, or a true round receptacle. Maybe different models of Apple computer have different receptacle designs. It doesn’t seem like a good idea to rely on that.

The other problem is the vertical height of the whole DB-19 substitute assembly. The current DB-19 adapter has only a male DB-19 at one end, with a height of about 3/8 of an inch. But the new, reduced size DB-19 substitute assembly has a PCB directly behind the pins, with a height of about 5/8 of an inch. For most Apple computers, the extra height is no problem. But for a few systems with recessed disk connectors, the extra bulk bumps into the plastic above the recessed connector, preventing it from being fully plugged in. On an Apple IIgs, it just barely fits. On the daisy chain connector of an Apple 3.5 Drive, it doesn’t fit.

Alternate Ideas

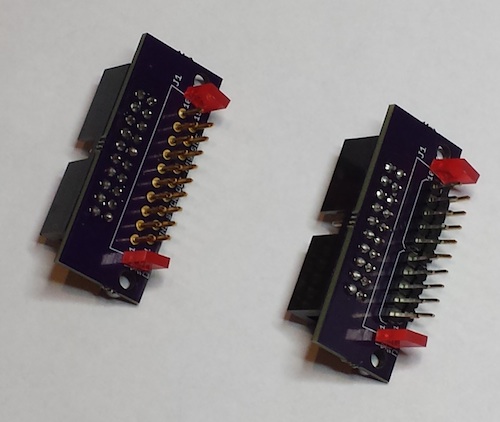

What to do? I’m probably going to abandon the idea of using 0.1 inch male header, as it just doesn’t seem reliable. Another option is to use 19 individual D-SUB crimp pins, soldered into the DB-19 substitute PCB. I built one of these last year, and it’s shown at left in the photo below, along with the first generation of the 0.1 inch male header substitute.

The version with the D-SUB crimp pins is definitely more reliable, but it’s a nightmare to assemble. Crimp pins aren’t designed to be soldered into a PCB like this, and to prevent solder bumps on the pin side from shortening the effective pin length, the pins need to be soldered from the “wrong” side of the board using an ugly technique. Individual pins won’t stay straight while soldering, so a female DB-19 must be used as a jig during assembly. And when it’s done, the crimp portion of each pin must be cut off with shears. The current DB-19 adapters are factory assembled with a mostly automated process. This crimp pins design would require a cumbersome manual process, driving up the cost, if the factory was even willing to do it. And the problem with the height of the assembly would still remain.

The other option is to find a D-SUB factory that could manufacture new male DB-19 connectors. I checked into this last year, and it looked like a tough road. Negotiating that kind of manufacturing deal is difficult for someone like me, with no industry contacts or big name credibility. Most places didn’t even respond to my emails. From those that did, it looked like setup costs would be around $10,000 before they could make even a single part. Given the small scale of my business, that’s not realistic. I’d have to buy a virtual lifetime supply of DB-19 connectors, and hope that Floppy Emu sales continued on pace through 2030 or so.

This just became my new #1 problem. I’m going to work on brainstorming other solutions involving D-SUB crimp pins or other round pins, and also make another set of inquiries for manufacturing new DB-19 connectors. The clock is ticking…

February 23 Addendum

After mulling this over for a while, I’m coming to the conclusion that I should get new DB-19 connectors manufactured, even if it costs $10,000. It’s the only solution I’m confident will work reliably. Everything else I can think of is a trade-off of quality for cost, and nobody’s going to be happy if I switch to a new style of DB-19 substitute that’s not always reliable or that has trouble fitting certain computers.

The cost of manufacturing new connectors is high, but the alternatives aren’t free either. I priced out one possible alternative involving an empty DB-19 male housing and 19 crimp pins, and it would cost about $5 per connector including the increased labor cost to assemble it. At the current sales rate, I’d be spending about $2000/year for a solution that’s inferior to a real DB-19. Compared to that, $10,000 doesn’t seem quite so unreasonable. The other alternatives I described earlier would be cheaper to build, but seem to have reliability problems, so they’re not really viable.

I’ve been using the number $10,000 as a rough figure, but it may be less than that. Assuming the best quote I received a year ago is still valid, it would be roughly $8000 to get 10,000 DB-19 connectors manufactured and delivered. That’s about one third of the total profit I made from all BMOW product sales last year. So it’s a big number, but not completely out of the question. I don’t need 10,000 DB-19 connectors, but I could probably resell some of those over the next few years and recoup $1000 or so of the manufacturing cost.

I’ve been talking with a person at IEC about splitting a new manufacturing run with them, which would help a lot if we can reach an agreement. Another possibility is to run a GoFundMe campaign and solicit donations to “save the DB-19″. If I could get enough vintage Apple enthusiasts to chip in $10 or so, it might make a significant dent in the manufacturing cost. Maybe I could put the names of the largest donors in the silkscreen of the adapter PCB.

At the end of it all, there’s just something cool about the idea of being the guy who resurrected the DB-19. Then the world can stop seeing sad pleas like this one. Maybe I’m insane, but that’s got to be worth something.

The post DB-19 Substitute, Take Two appeared first on Big Mess o' Wires.